Depending on the scale and purpose, pasta and macaroni machines come in various types. Below are the most common ones: A. Manual Pasta Machines These are small machines operated by hand, ideal for domestic or small commercial setups. They are suitable for fresh pasta but not for large-scale or industrial production. Features: Compact and easy to use Ideal for cafes or restaurants Limited production capacity B. Semi-Automatic Pasta Making Machines These machines combine manual and automatic operations. The operator feeds ingredients manually, while extrusion and cutting are automated. Features: Medium production capacity Lower initial investment Easier to maintain

About Abcot Machinery

The Best Paper Plate Making Machine Manufacturers in noida

Have any custom requirements?

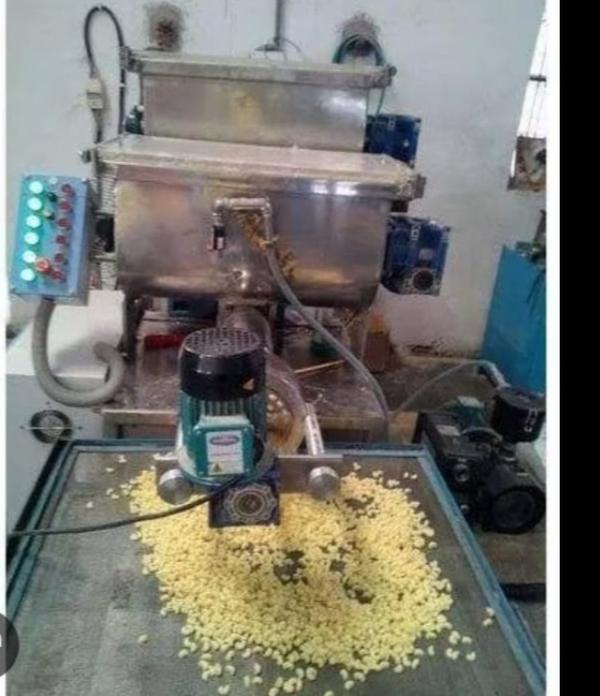

Image Gallery

Pictures That Speak

×

![]()